Amputee Apparel for Mt. Kilimanjaro Climb

Overview

Project Background

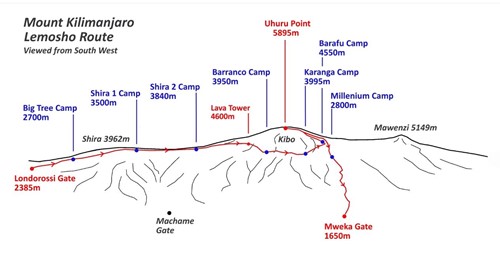

Our client, Travis McCody, is a bilateral transfemoral amputee Army veteran. This means Mr. McCody is an above-knee double-leg amputee. He normally uses a wheelchair for everyday activity, but Mr. McCody continues to stay active by doing what he enjoys such as hiking. He has recently completed the Manitou climb and summited Pikes Peak. Mr. McCody must adapt to be able to hike and relies heavily on his hands and upper body strength to summit the mountains. He has been an amazing advocator for injured veterans and continues to take on challenges to inspire others and raise awareness of the adversity injured veterans face. He currently has a climb scheduled for the summer of 2021 to summit Mt. Kilimanjaro. The Kilimanjaro hike that Travis will be taking is called the Lemosho climb. This climb is the most scenic of the hikes and provides the best ability to summit Kilimanjaro. Lemosho is one of the longer routes which allows the climbers a better ability to acclimate to the climate and the altitude. Still, this is no easy task as the Lemosho climb is 42 miles with 4 different climate zones that the climber’s experience [1]. The climbers will be going through the rainforest, moorland, semi-desert, and alpine desert. Our teams were tasked with the objective to design and deliver a pair of pants and gloves to Mr.McCody that can withstand the journey to the summit of Kilimanjaro.

There have been climbers with transfemoral amputations that climbed large mountains like Kilimanjaro. Kyle Maynard climbed Kilimanjaro with bilateral transfemoral amputations with carbon fiber sockets that he put both of his residual limbs into [2]. These looked very tough and provided an idea of how to truly protect Mr. Strong’s residual limbs. Jaime Overmyer from Breckinridge Outdoor Education provided some insight into what they use for their climbers with disabilities. Overmyer said they like to look towards products that already exist such as hockey gear or catcher’s pants [3]. Overmyer provided useful information that the project does not need to go outside the box, there may be products or designs that already exist that will provide great protection for Mr. Strong while climbing Kilimanjaro.

In an interview with Travis, we learned that a major obstacle that he has faced in previous climbs is his pants and gloves wearing down throughout the hike and either tearing or ripping leading to exposure of his residual limbs and hands to the environment and this leads to debris getting into pants and glove area, This has led to cuts and abrasions forming on the skin and by the time he has completed his hikes, his gloves and pants would be blood-soaked. Travis has powered through this on previous climbs, but in comparison to hiking up Kilimanjaro, they are much shorter and have not required a multi-day journey. The unforgiveness of the environments that Mr. McCody will experience during his hike of Kilimanjaro and the length of his journey has led to these projects. If his pants were to fail as they have on other climbs, the cuts and abrasions Travis might experience might become infected and lead to the end of the climb before it is completed. After talking to Travis about his hiking technique and major concerns for the design of the pants, several ideas were thought of. The most important thing he pointed out was the padding on his buttocks and the ends of his residual limbs and to limit the amount of debris that gets into the pants. To do this, we had to consider the environments that Travis would face on his hike and find a pants material that provided the necessary properties to maintain longevity throughout the trip. Padding was added in keys areas of the pants based on Travis’s hiking technique and the areas of the pants that experience the greatest wear and tear.

Similar to the pants team, the gloves need to be resistant to wear in very particular places. As seen below Travis frequently walks on his knuckles as well as his palms, this creates frequent and uneven abrasion reducing the efficacy of off-the-shelf gloves. Therefore, our team strived to create a set of gloves that could withstand the moisture and jagged rocks found along with mount Kilimanjaro. We completed this task by adding reinforced leather to a multitude of areas and sealing the gloves with waterproof material. Our design guarantees an increased lifespan and cycle limit which should help Travis maintain healthy hands while on his journey.

Live Zoom Chat

Use the link below to join us live from 8:00 – 10:30 a.m. on April 29th.

Join from PC, Mac, Linux, iOS or Android: https://mines.zoom.us/j/97388344727?pwd=elBtcDZ5cm5PNzczYjRMR1lOS1ZYZz09

Password: 249093

Or iPhone one-tap: 13462487799,97388344727# or 16699006833,97388344727#

Or Telephone:

Dial: +1 346 248 7799 (US Toll) or +1 669 900 6833 (US Toll)

Meeting ID: 973 8834 4727

International numbers available: https://mines.zoom.us/u/aewxo6fLXd

Team Members

Gloves Team

- Isaiah Warnick – Project Lead

- Chloe Smith – Project Lead

- Casey Langenbahn

- Garron Tubbs

- Koby Dudley

- Faith Gilb

Pants Team

- Ashlyn Orr – Project Lead

- Mack Minnehan – Project Lead

- Landon Le

- Renato Leyva-Hernandez

The Client

- Travis Strong

- Scott Huyvaert and Quality of Life Plus (QL+)

Acknowledgements

Project Advisor: Joel Bach and Chelsea Salinas

The team would also like to thank our Human Centered Design Studio project advisors Joel Bach and Chelsea Salinas.

The team would like to thank Travis McCody, Scott Huyvaert, and QL+ for the opportunity to be a part of this amazing climb.

Donations Made by: QL+

Video

A special thank you to Travis and Bradley Kussy for letting us use some footage from their documentary, No Limits which can be found here: https://www.youtube.com/watch?v=78lqEalvm58

Elevator Pitch

At the Human Centered Design Studio, group members mesh together their problem-solving skills along with their desire to improve the quality of one person’s life to the next. It is important to us to find what our clients enjoy doing, and how we can help make that happen. Travis Strong embodies this persona incredibly, as he has used his platform to spread awareness for disabled veterans and first responders. Travis once stated, “Just because you don’t have legs, you can still go out and do whatever you want to do,” as he continues to build awareness by summiting challenging hikes across the country. Travis is so determined that he has summited with water and blood-soaked pants, along with immensely irritated hands, which is why we want to provide a better solution for his future endeavors.

Our Client, Quality of Life Plus (QL+), reached out to us in the fall of 2020 with a “challenger”, Travis Strong. Our projects were split into two different teams to build Travis suitable apparel for his upcoming climb to Mt. Kilimanjaro, in the Summer of 2021. Both designs would have to provide sufficient padding for Travis, as well as being durable enough to take on the intense environments the Lemosho Trail presents. The teams achieved their goal by providing Travis with a pair of protective gloves, and padded pants. Ease of repair, comfort, and versatility were held to a high standard for both designs.

Design Approach

Gloves Team

The team began the design process through the exploration of the current gloves Travis uses to climb with. Upon interviewing Travis the team learned of his current concerns and issues with his gloves. The project goals included keeping Travis’s hands safe from scratching and bruising, dry and warm, to keep his wrists supported. With past gloves Travis had issues with seams ripping and holes being worn into the gloves from all of the cyclical use. The team then compared the initial ideas with the design goals that were generated following the client meeting through many decision matrices in order to ensure the created product will withstand the long and difficult climb up Kilimanjaro. The design ideas were weighted against our project goals. Once initial designs were determined and the priorities of the goals were determined the team began initial material research.

The team acquired various materials and material samples for testing. The team needed to determine the best material for the base of the glove, the padding in the glove, and the outer protective layer of the glove. Depending on the desired end use of the material the team preformed different tests and evaluated different properties and standards on the materials. When material were found that held up to the tests the team preformed on them and therefore would be suitable for the climb the team was ready to prototype using these materials.

The team then tackled the building process of the gloves. This included many of the team members learning how to use an industrial sewing machine. The team also researched different threads and seam types to find the best ones to use for the gloves. The team also decided to use an adhesive on the glove for reinforcement. The team preformed testing on multiple adhesives to determine the one that was the most compatible with the materials. The team created a prototype and sent it to client for feedback.

Pants Team

The pants team took a similar approach to the gloves team; beginning the project by identifying how the pants Travis previously wore could be improved. With the glove team, an interview was conducted to help spot the key features Travis would need. The project goals that ensued were: sufficient padding for the glute and hip regions, weatherproof, durable pants, and providing the pants with a repair kit. Travis notified that the pants he used to hike in previously would allow for debris to enter, which would lead to rashes and irritation. Furthermore, Travis let us know that he usually climbs with open cargo shorts, providing no padding whatsoever. Lastly, it was brought to our attention that Travis’s left extremity is 2″ shorter than his right side. Because of this, the team did extensive research on different pant materials, thread materials, and padding to ensure the materials can withstand the intense climb, and to Travis’s exception. To do so, the team put together a decision matrix with factors weighted towards achieving our project goals.

The team then put together a material list, including: pants, padding, and thread. Our major concerns revolved around durability and comfort. This meant that the pants must be able to withstand the multiple environments that Mt Kilimanjaro presents, as well as not hindering Travis’s performance. The padding materials were determined by body region, and the accompanied climbing techniques that Travis would commonly use. The team ran multiple tests to appropriate which materials would perform best under the given climbing techniques.

Once Travis okayed our design, we began our building phase. This included the use of an industrial sewing machine, similar to the gloves team. The team retrieved measurements via Travis that would help locate the padding for the hips and the glutes, as well as providing a length for the pants. Following research on correct thread material and stitch length, we sewed the pads into place. The hip pads were deemed to remain permanently stitched in the pants, while the glute pads could easily be removed. The team created their prototype and sent the design to the client for feedback.

Design Solution

Pants

The team created a pair of pants for the original prototype and sent it to the client. The client liked the design, so the team moved forward with creating the same design. Both sides of the legs were cut to length and sewn off. The pockets for the glutes were double layered and fit to the shape of the pad. The pocket material was made out of a flexible nylon fabric to make putting the pads into place a simple task. The hip pads were made of a single layer of fabric and a small hole was created for the pad to get put into. The pant material fit the needs required by the team: a 65/35 polyester to cotton blend that provided a waterproof layer, was durable, and the stitching did not encourage debris to get in. The design goals the team could test without the client met the goals the team had set at the beginning of Fall of 2020.

Pads

There are two different pads used on the pants. The pad for the glute is a hard-shell pad because of the way Travis likes to climb up backward. The glute pads need to be rigid upon use to ensure the shearing force does not damage the pad. The glute pads are able to fit Travis’s lower extremities to a custom fit, forming to the surrounding surface when exposed to air. After approximately thirty minutes of forming, the pads transform from a gel-like enclosure to a hard, rigid, and lightweight forming pad. The pads used for the hips have some porosity and are soft, simply to add enough protection to the hip pointers on the occasion that Travis is fatigued, and uses a lateral climbing technique as indicated in our initial interview. The pads on the hips are not hard because that would impede the range of motion which is incredibly important for the climb. The pads were picked due to their hexagonal geometry, which is favorable upon distributing forces. The pads are held via a nylon fabric to allow for material flexibility, as well as keeping the pockets secure inside of the pants.

Thread

The thread used for the pants is a Nylon Thread, due to the fact that nylon is very durable and can withstand a lot of forces. The thread was done on a stitch length of three which creates tight stitches to ensure debris cannot get into the pants. The end of the pants and around the pockets have two lines of stitches. One stitch is a zig-zag stitch, and the other is a straight stitch to provide as much durability and structure to the pants and pockets as possible.

Pants

The pants chosen by the team were waterproof and provided good durability during the testing. The pants are labeled as lightweight tactical pants which fits the needs for the climb, due to the multiple different weather conditions upon the Lemosha Trail. The pants are 65% polyester and 35% cotton. They are water repellant which is desired by the team. The pants are earthy colors as requested by the client.

Gloves

Travis and the team at QL+ have tasked us with retrofitting an existing pair of gloves to make them more abrasion-resistant on the knuckles and palms. Initial designs were made to sew a completely new set of gloves, but this design quickly lost steam due to the intense labor and sewing skills needed to sew professional gloves. After reviewing the material testing on multiple types of leather, the team decided to go with goatskin for its superior abrasive resistance and its flexibility to fit Travis’ hands without causing irritation. The team decided to add protective areas to the gloves using Bedliner to provide an abrasion resistive surface as well as extra padding to provide comfort. To protect the wrists, wrist straps were purchased by the team to better support Travis when he walks on his palms. These straps are typically used for lifting but supply excellent protection for this application as well when support is needed to reduce wrist flexion.

Gloves

To achieve the desired level of abrasion resistance while still allowing the gloves to remain flexible, a rubberized material used for pickup truck Bedliner known as Line-X was used for high-wear sections of the gloves. The Line-X sections were created using a stencil held above a simple cotton fabric, which was then cut into the required pieces. The pieces used in the stencil came from a disassembled prototyping glove. They were originally used as leather reinforcement in key areas of the glove, as the palm and back of the hands. The team also decided to craft some novel stencils for the fingers as well. Altogether, the stencils created amounted to about three gloves of material to allow for some extras. These pieces were glued and/or sewn onto the gloves in the desired locations. With these Bedliner sections of the gloves attached, the abrasive wear resistance of the gloves will be greatly improved, along with additional increases in overall protection. The figure below shows the initial cuts of material before trimming, refinement, and attachment.

Waterproof

Using a natural waterproofing material, the team decided to increase the applicability of the gloves in wet climate zones to keep Travis’s hands dry and protected from excess moisture. However, this will lead to an increase in sweat from Travis’ hands so we have recommended to him to let the gloves “air” out three times a day to help maintain healthy hands.

Wrist Protection

This solution was already designed and manufactured. These wrist straps are an optional component to our gloves, but they provide safety against sprained wrists and overextension while moving around. The design starts at a thumb loop and wraps around the wrist to the user’s desired tightness. The tighter the glove the more protection against injury but also the greater chance for the user to lose necessary circulation to the hands. The wrist straps will prove an asset to Travis as he ventures up and down Kilimanjaro.

Next Steps

Gloves Team

Gloves Team

All of the remaining work on the gloves to Travis’ climb lies in the feedback we receive from the current prototype he has. This will ensure that our client has the best product possible. The team will also make a second set of glove to be taken on the climb with Travis to ensure he always has gloves to wear on the long climb.

The next steps include:

1.Getting final feedback on the team’s latest prototype.

- Complete a final design iteration to address client feedback.

- Assemble final product with adjustments

- Test final product once assembled

- Send final product to client for use this summer.

Pants Team

- Contact with a prosthetist would be ideal for the shorter residual limb. Giving him a prosthetic to accommodate for the imbalance in his leg lengths, as well as providing its own comfort and durability, would greatly improve the pants project.

- Being able to design our own pads. Find ways to make custom-forming pads that we can add to the design.

- More documentation and continuous feedback from Travis. Given Travis is located in another state, it is crucial that he communicates the pitfalls and highlights of the apparel.

- This project is made for an event that is happening this summer, the pants created will not be further updated for the needs of Kilimanjaro.

Meet the Team

Ashlyn Orr - Pants Team - Project Lead

Ashlyn Orr will be graduating with her BS in Mechanical Engineering and a minor in Biomechanical Engineering. She will be continuing her studies at Mines studying Materials and Metallurgical Engineering. As project lead, Ashlyn makes sure the client gets all the details to the client to ensure they are up to date with progress and can give feedback as needed. Outside of school, Ashlyn enjoys spending time outside with her dog.

Ashlyn Orr will be graduating with her BS in Mechanical Engineering and a minor in Biomechanical Engineering. She will be continuing her studies at Mines studying Materials and Metallurgical Engineering. As project lead, Ashlyn makes sure the client gets all the details to the client to ensure they are up to date with progress and can give feedback as needed. Outside of school, Ashlyn enjoys spending time outside with her dog.

Mack Minnehan - Pants Team - Project Lead

Mack will graduate this spring with a BS in Mechanical Engineering. He plans to continue his education with a focus in Biomechanics, while having project management experience. As a project lead, Mack focusses on making a quality product, adapted to each client. Outside of his schoolwork, Mack plays outside linebacker for the Colorado School of Mines.

Mack will graduate this spring with a BS in Mechanical Engineering. He plans to continue his education with a focus in Biomechanics, while having project management experience. As a project lead, Mack focusses on making a quality product, adapted to each client. Outside of his schoolwork, Mack plays outside linebacker for the Colorado School of Mines.

Renato Leyva-Hernandez - Pants Team

Renato will be graduating this Spring with a BS in Mechanical Engineering. He plans on starting his own trucking business and eventually transition into the automotive industry as an engine test engineer. Outside of school, he enjoys spending time with his family, playing sports, and working on trucks with his older brother.

Landon Le - Pants Team

Landon will be graduating this fall with his BS in Mechanical Engineering. He plans on working as a Project Engineer Intern in the upcoming summer and hopes to continue a career in project management after graduating. He enjoys playing handball, fishing, and hanging out with friends and family in his free time.

Landon will be graduating this fall with his BS in Mechanical Engineering. He plans on working as a Project Engineer Intern in the upcoming summer and hopes to continue a career in project management after graduating. He enjoys playing handball, fishing, and hanging out with friends and family in his free time.

Isaiah Warnick - Gloves Team - Project Lead

Isaiah is a graduating senior in Mechanical Engineering. He enjoys spending time with friends and family, playing video games, and playing sports. Throughout school, Isaiah has been a part of the Navigators and the Air Force ROTC program through CU Boulder. He will be commissioned as a 2nd Lt into the Air Force after graduation. In the Air Force, Isaiah will be going to pilot training at Laughlin AFB (Date to be determined).

Isaiah is a graduating senior in Mechanical Engineering. He enjoys spending time with friends and family, playing video games, and playing sports. Throughout school, Isaiah has been a part of the Navigators and the Air Force ROTC program through CU Boulder. He will be commissioned as a 2nd Lt into the Air Force after graduation. In the Air Force, Isaiah will be going to pilot training at Laughlin AFB (Date to be determined).

Chloe Smith - Gloves Team - Project Lead

Chloe will be graduating this spring with a BS in Mechanical Engineering and a minor in Computer Science. In the fall she will be working management. She has enjoyed this project and the experience it has given her. Outside of school she enjoys spending time with her dog, Blue, skiing, and being with friends and family.

Chloe will be graduating this spring with a BS in Mechanical Engineering and a minor in Computer Science. In the fall she will be working management. She has enjoyed this project and the experience it has given her. Outside of school she enjoys spending time with her dog, Blue, skiing, and being with friends and family.

Casey Langenbahn - Gloves Team

Casey is currently a dual-enrolled Graduate and Under-Graduate student. He plans to graduate in May with his degree in Mechanical Engineering and then again in December also with Mechanical Engineering. Casey served on MAC and is very involved in promoting healthy student life.

Casey is currently a dual-enrolled Graduate and Under-Graduate student. He plans to graduate in May with his degree in Mechanical Engineering and then again in December also with Mechanical Engineering. Casey served on MAC and is very involved in promoting healthy student life.

Garron Tubbs - Gloves Team

Garron is a graduating mechanical engineering student planning to return to Colorado School of Mines for his master’s degree, where he will specialize in biomechanical engineering. In his free time, he enjoys outdoor activities like soccer, hiking, and skiing. He is excited about the progress of this project and eager to see it finally in use.

Garron is a graduating mechanical engineering student planning to return to Colorado School of Mines for his master’s degree, where he will specialize in biomechanical engineering. In his free time, he enjoys outdoor activities like soccer, hiking, and skiing. He is excited about the progress of this project and eager to see it finally in use.

Koby Dudley - Gloves Team

Koby is a senior in mechanical engineering Mines from Castle Pines, Colorado. He is a high jumper on the school track team and joined the Human-Centered Design Studio in the fall 2020 semester. In his free time, he likes camping, mountain biking, and exploring off-road trails. After graduating, he wants to find a job in the automotive industry.

Castle Pines, Colorado. He is a high jumper on the school track team and joined the Human-Centered Design Studio in the fall 2020 semester. In his free time, he likes camping, mountain biking, and exploring off-road trails. After graduating, he wants to find a job in the automotive industry.

Faith Gilb - Gloves Team

Faith is a graduating mechanical and biomechanical student at Colorado School of Mines. After Mines, she will be taking some time off to work and gain experience before returning to graduate school to pursue biomechanical engineering. In her free time, she likes to read, play board games, and hang out outside. She is also beyond excited about this project and is excited for its application soon!

Citations

[1] Lemosho Route, 03-Nov-2018. [Online]. Available: https://lemosho.com/ . [Accessed: 29-Oct-2020].

[2] “No arms, no legs? No excuses – Amputee to Climb Kilimanjaro,” CBS News, 18-Oct-2011. [Online]. Available: https://www.cbsnews.com/pictures/no-arms-no-legs-no-excueses-amputee-to-climb-kilimanjaro/. [Accessed: 26-Apr-2021].

[3] A. Orr and J. Overmyer, “What Breckenridge Outdoor Education Uses for their Climbers with Disabilities,” 30-Sep-2020